When people think about packaging, design is the first thing that often comes to mind. While aesthetics matter and packaging must protect your product, there are other critical factors to consider when evaluating—or re-evaluating—the right packaging material.

Lightweighting is an often-overlooked consideration in the packaging selection process that often can impact various parts of the business. Does it streamline filling or packing? How does it impact logistics costs? Does it use more material than it needs?

When we work with our customers to enhance the efficiency of their packaging, lightweighting is a key focus. Lightweighting involves reducing the material weight of packaging, while maintaining its performance. In other words, can you use less packaging and provide the same level of protection and durability?

Packaging your products for protection is essential, but durability doesn’t necessarily mean you need excess material. In many cases, packaging is over-engineered, or uses more material than necessary to achieve the same level of protection. That’s why lightweighting is an important consideration: it helps strike a good balance between performance and efficiency.

Packaging your products for protection is essential, but durability doesn’t necessarily mean you need excess material. In many cases, packaging is over-engineered, or uses more material than necessary to achieve the same level of protection. That’s why lightweighting is an important consideration: it helps strike a good balance between performance and efficiency.

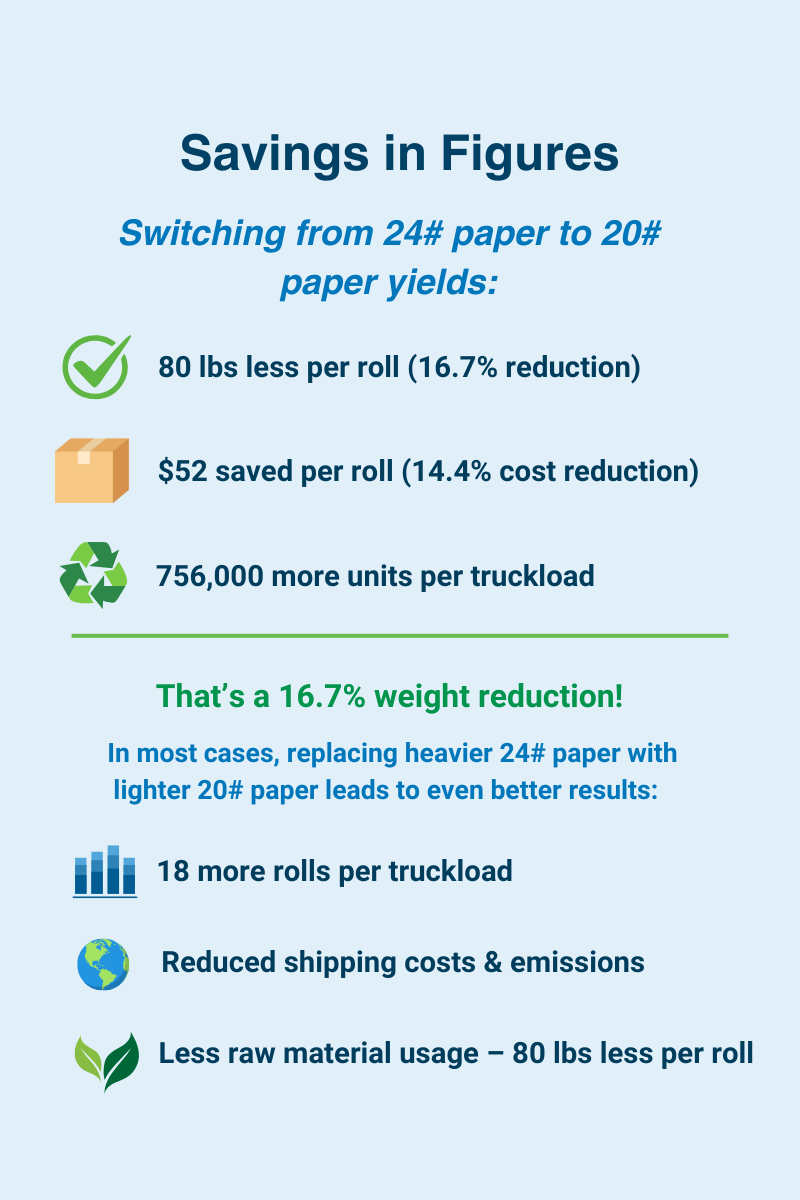

Our discussions around lightweighting typically focus on a few key benefits:

- Cost Reduction: Using less material lowers raw material costs and reduces shipping and logistics expenses. Lighter packaging means lighter shipments, which can significantly reduce logistics costs over time.

- Sustainability Gains: Lightweighting reduces materials, cuts waste and lowers carbon emissions from production and shipping. It can help meet sustainability targets while aligning with consumer demand for more eco-friendly packaging—without compromising performance.

- Regulatory Readiness: While lightweighting isn’t typically mandated by legislation, it can be a smart long-term strategy for optimizing your packaging, particularly if a previous regulatory-driven packaging change was implemented quickly and wasn’t ideal. Evaluating the material usage can help refine your packaging to better align with both compliance requirements and operational efficiency.

- Performance Optimization: Packaging needs evolve. If it’s been a while since you’ve evaluated your product’s packaging, evaluation can identify opportunities to trim excess weight without compromising performance.

Key Considerations for Lightweighting Your Packaging

The important thing to note is that lightweighting isn’t necessarily a one-size-fits-all solution. Some companies find that the trade-offs outweigh the benefits. A good example is a customer that did a lightweighting audit and found that the potential risk of damage to their product wasn’t worth the lighter packaging.

Here are just a few things to consider:

- Product Protection: Lighter materials may not provide the same level of protection as heavier alternatives, which may be particularly relevant to fragile or perishable goods.

- Manufacturing Constraints: Some packaging machines may not handle thinner paper and will ultimately slow down production speeds, increase scrap rates or require significant adjustments that make lightweighting infeasible.

- Cost-Effectiveness: Despite achieving cost savings in logistics, transitioning to a new material or process may cost more in terms of upfront investments and machine retooling.

- Material Substrates: Switching to a lightweight paper alternative can change production and protective capabilities when your primary packaging material is plastic. Rigorous testing is essential, as not all products are well suited for this transition.

When Lightweighting Might Not Be a Fit

Cost and performance are two primary reasons why people may decide not to lightweight their package. Here are a few other reasons why it might not be the ideal choice:

- You need better protection. Products that are perishable, moisture-sensitive or require specific environmental controls, like electronics or food items, may need robust packaging that lightweighting could compromise.

- Your product is fragile. When items such as glassware can be easily broken in transport, reducing packaging materials could lead to increased product waste and higher costs in the long run.

- It poses manufacturing challenges. If a material change results in cost savings, but causes your production to slow down, the overall impact may be negative. For example, if switching materials saves 10 percent in costs but requires a 20 percent slowdown to maintain the quality, the trade-off may not be worth it. At JBM, we’ve seen firsthand how even switching to a different raw material at the same weight can create operational challenges, let alone trying to replace the base material entirely.

How to Decide If You’re a Good Candidate for Lightweighting

If you’re looking at your packaging and trying to decide if it’s the right choice for your product, here are a few questions to ask:

- What does your packaging need to do? As a first step, you should identify the primary function for your packaging. Do you need to see inside the package or does the package simply serve to protect against the elements? Is moisture or grease protection important? Do you need it to withstand long shipping times or hold up in a retail environment? Having a clear grasp of these performance requirements will enable you to determine if a lighter material can meet your needs.

- Is cost savings a primary goal? While lightweighting can lead to cost reduction, you may find that these savings don’t compensate for the increase in production costs. Identify all costs associated with the effort including freight, materials and production, to assess whether lightweighting will save money.

- Do you currently use too much packaging? There’s a chance that your existing packaging materials are more than you need. If you haven’t right-sized your packaging to identify the correct thickness or performance requirements, you might be a good candidate for lightweighting. You should also evaluate your primary and secondary packaging to identify additional opportunities for lightweighting.

- Will lightweighting support your sustainability goals? If your organization has a sustainability program in place, lightweighting may help contribute to your environmental targets. By using less material, lightweighting decreases resource consumption, has limited impact on the manufacturing process, minimizes emissions and lowers the overall lifecycle impact of your packaging. It can also align with consumer demand for more eco-friendly products.

- Are you ready for extensive testing? A lighter package must still perform reliably, which requires rigorous testing. This includes strength and durability testing to ensure it withstands shipping and handling, lifecycle assessments to assess sustainability impacts and real-world application testing to confirm the new material won’t compromise protection. Material comparisons are also essential to find the best balance between weight, functionality and cost. Skipping this step can lead to package failures, increased product damage and costly redesigns.

The Bottom Line: Lightweighting is a Strategic Decision

For some businesses, lightweighting is a game-changer. It can improve efficiency and support sustainability goals. For others, the trade-offs may not make sense given their product requirements. The key is to approach the decision with clear objectives, solid data, and expert support. This is just one of the many value-added services we offer our customers to make sure their packaging fits their needs.

Thinking About lightweighting?

Let’s evaluate your packaging specifications together and find the right balance for your needs.